Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

[ad_1]

It will require the production of automation, tools, infrastructure and training for decades for decades for decades for decades. The promotion of foreign components to create facilities in the United States will also be difficult.

“If you’re a kind of component that can be used on a Huawei or an Xiaomi phone, you used you,” he said. “It’s low to separate these factories because if the apple was the only supplier, you get a scale and efficiency in China.”

According to TSAY, politics is another problem. “The American system is not entirely affordable for business investments, business investments every four years. When people and companies have invested, it is necessary to have a horizon longer.”

Mark Randall was a senior vice-president at Motorola, when Google belonged to Google and was trying to build a US smartphone factory. The idea was not possible, says, but I just knew it would be incredibly difficult. “

US labor expenditures are higher than other places to turn raw materials to the finished goods, “For example, we need tens of thousands of mechanical engineers.” We need tens of thousands. “

Tariffs create a “nightmare” when modeling the cost of a new plant, adds Randall. “Therefore, most companies do not create short-term and knee pink reactions in the form of changes today. You need to be super strategic and know where you are going for a long time.”

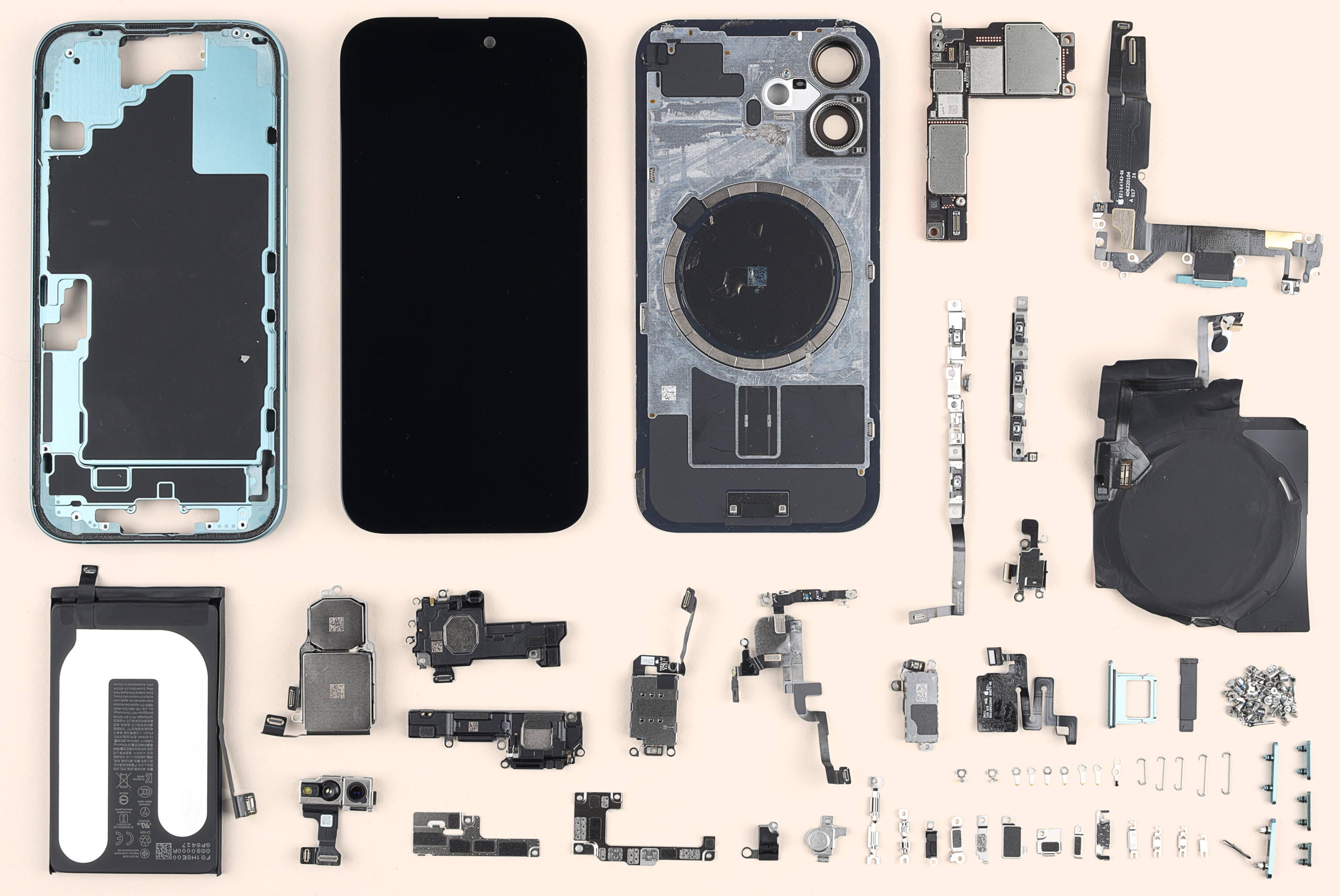

One profoundly look horse this supply chain for triple walnut in this last iphone Models be illustrated this complexities one moving production for this The United States, in one industry this required years for do even boost shifts.

Currently, a component on the woven screen prepared in the United States is a coating produced by a long time in Kentucky, although the company has facilities in China and India.

However, an integrated multi-woven layer, which allows you to interact on the screen and interact on the screen, which helps maintain the battery life is mainly produced by Samsung South Korea.

The main electronic parts of the screen are combined with the screen section in China in production enterprises before being carried into a foxconn plant to be combined with the rest of this component Iphone.

This metal frame neatly it takes this be out one overcome Chinese from Apple supply the chain. For most Models, this corps have cut off and formed from one block one aluminum use high-minute computer numerical control (CNC) machines.

An analytical Wayne LAM in Techseans, said that this process has relying on the “Army” in the provinces of apple vendors in China and the “army”. “If Apple was on land on the iPhone, there would be no CNC machines that they could buy to pay the scale of the Chinese ecosystem” Says.

Lam adds: “This is a qualified skill that cannot be repeated outside China.”

Even this iphone most component – her miniature screws – have Complex. They have fifty from differently material Depending on side themselves the role, and make rich one count one Heads: Philips, straight, Tri-pipe and pentalobe, between others.

However, if the company’s iPhone production is transferred to the United States, he said goodbye to the process where the difficulties will meet. Unlike many other smartphones in Apple, it does not use glue to close the framework, and analysts say that FoxConn is more efficient to hire people to hire more people than investing in robot solutions.

[ad_2]

Source link